| Manual drilling refers to several drilling methods that rely on human energy to construct a borehole and complete a water supply. The various techniques can be used in areas where formations are quite soft and groundwater is relatively shallow.Manual drilling can provide safe drinking water. The equipment can easily be transported to remote, or difficult to serve populations which would otherwise be left behind. The lower costs compared to machine drilling are appreciated by households, businesses and governments. Manual drilling also provides local employment. |  |

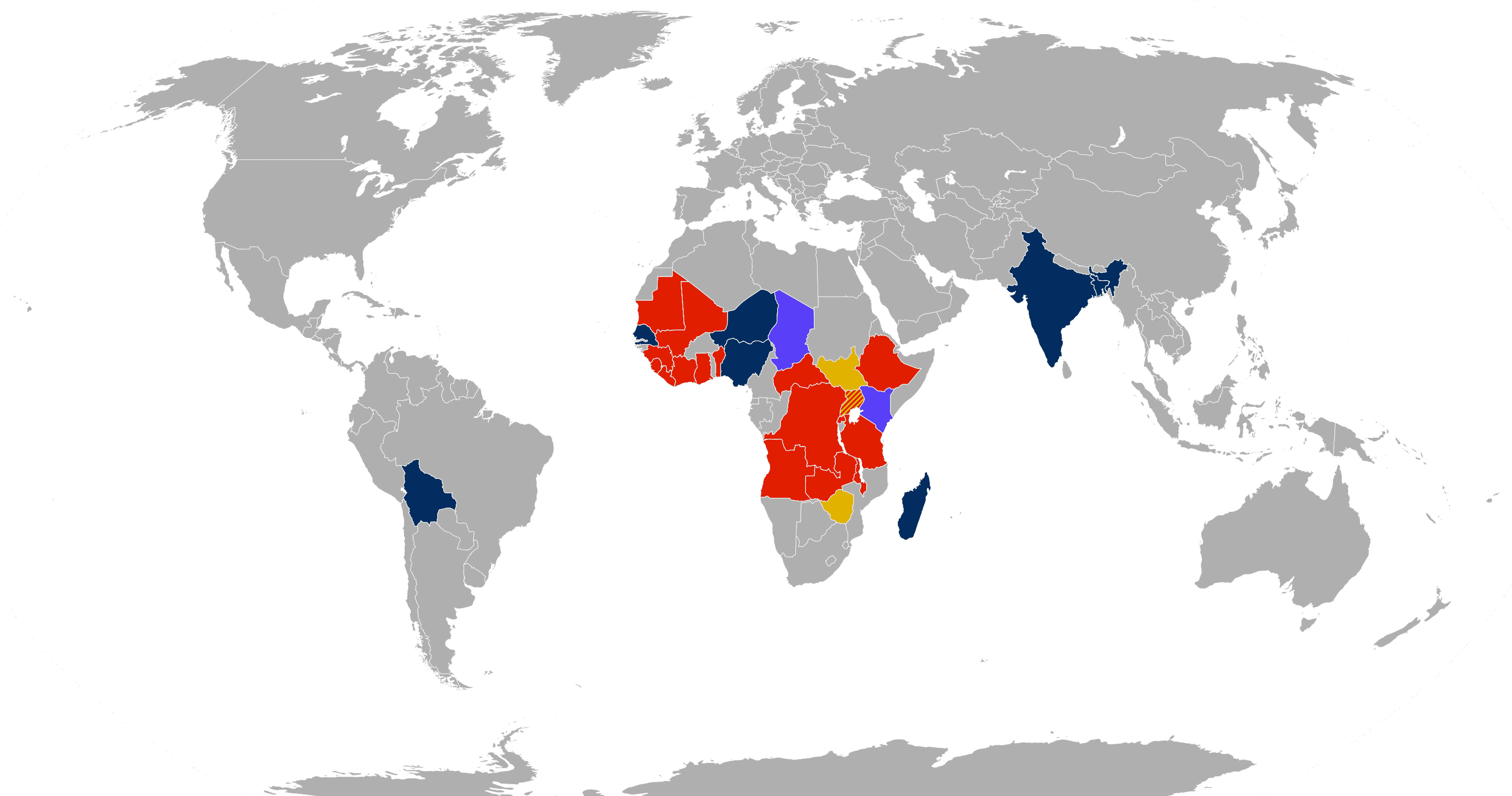

Manual drilling methods are being used to provide water for drinking and other domestic needs at least 36 countries around the world. In some places, manual drilling methods are well established.

Manual Drilling is part of the RWSN Professional Water Well Drilling topic.

This website catalogues key reports, videos and links on technical and broader aspects of manual drilling. You can also click here for all manual drilling publications available on the RWSN website (English Filter & French Filter).

Worldwide Overview

|

|

Specific Country Experiences

|

Manual Drilling - A global perspective of local realities. UNICEF/RWSN Webinar Series 2014. Five webinars (recordings, presentations and learning notes) examine the successes and challenges experienced by different organisations involved in manual drilling in:

|

|

Bolivia |

|

Chad

|

|

Democratic Republic of Congo |

|

India |

|

Madagascar

|

| Malawi |

|

Niger |

Nigeria

|

|

Panama |

|

South Sudan |

|

Uganda |

|

Zambia |

|

Zimbabwe |

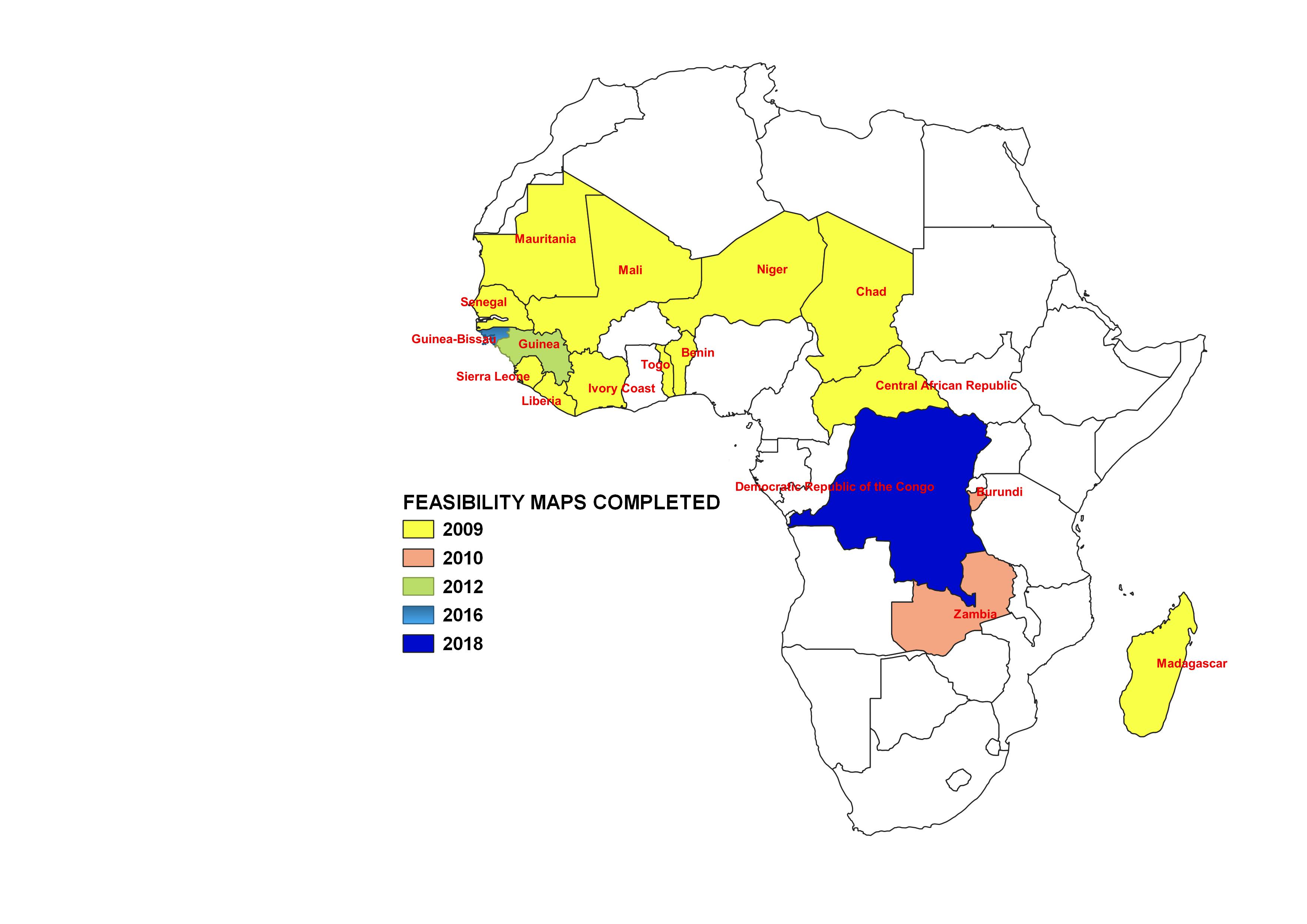

Maps and Reports of Manual Drilling Potential

|

Using existing borehole data, analysis and GIS technology, studies and maps of the potential for manual drilling are available for the following countries: |

|

UNICEF Toolkit for the Profesionalization of Manual Drilling

The toolkit supports African countries wishing to embark on the profesionalization of manual drilling. It includes technical notes and manualy, advocacy materials, mapping of suitable areas for manual drilling, case studies, and implementation and training manuals. This toolkit sets out how to builds the capacity of the local private sector in order to respond to the ever increasing demand for safe water in rural areas.

|

Technical Note Series on manual drilling (2009) in English and French 1. The Case for Manual Drilling in Africa |

|

Technical manuals for manual drilling (2010) in English and French 1. Professionalizing the Manual Drilling Sector in Africa |

|

Videos for the promotion of manual drilling in English and French |

Training

A very short introduction to manual drilling

Hand drilling is also known as manual drilling, human powered drilling, and is sometimes referred to simply as low cost drilling. As the names suggest, hand drilling technologies primarily utilise human energy.

The cost of a manually drilled well can 10% to 50% of machine drilled or hand dug well to similar depth. Hand drilling equipment can often be readily taken to sites which larger, more conventional drilling cannot access. However, it is important to note that hand drilling techniques are extremely effective in appropriate ground conditions. They are not suitable beyond their hydrogeological limitations. In cases where the formation is too hard, or the water bearing formation too deep, conventional drilling is the preferred option.

Unlike hand digging, which requires a person to be physically below ground to dig the well (of at least one meter in diameter), hand drilling enables the operators to remain above the ground and drill a narrow diameter borehole (50 to 200mm). Hand drilling can provide highly affordable improved groundwater sources for households and communities for both domestic and productive use. Drilled depths depend on the technology and formation, but can extend to 30m and sometimes more.

The auger method involves penetrating the ground with a small-diameter borehole with a cylindrical or helical soil auger. This method can penetrate certain sands and silts and some clay formations.

Hand percussion and stonehammer drilling involve the lifting and dropping a cutting tool suspended at the end of a rope. They are dry techniques, only adding a little water in order to remove the spoil (drill cuttings).

In contrast to the above, the jetting and sludging methods use considerable amounts of water to wash out the spoil. Jetting (also known as washboring) and the EMAS technology inject water down and out the bottom of a drilling pipe to wash the spoil up to the surface. Self-jetted well-screens are an improvement of the original jetting technique. The use of a cutting point when jetting enables more compact materials to be drilled. A tripod (or derrick) enables the technique to penetrate deeper. The EMAS technique uses a percussion action coupled with back and forth rotation of the drill bit to break the formation, whereas jetting is designed to penetrate mainly sands and silts with the force of the jetted water.

Sludging and its more recent modifications (Baptist, Rota Sludge and Pounder Rig) are all continuous drilling methods that allow the drilling fluid to flow down the annulus (ie the gap between the drill pipe and the drilled hole) and carry the cuttings up through the drill pipe. The Baptist method, Pounder Rig and Rota sludge have all tried to penetrate harder formations, with varying success. The Pounder Rig places the more emphasis on drilling of a vertical hole, whereas the Baptist and Rota Sludge techniques emphasise very low cost wells. The Baptist and Rota Sludge techniques can be combined with stonehammer drilling to penetrate harder formations (eg laterite) whereas the Pounder rig is already designed for this.

For a comparison between different hand drilling methods and other drilling techniques see:

- Human Powered Drilling Technologies. An overview of human powered drilling technologies for shallow small diameter well construction, for domestic and agricultural water supply by R.C. Carter, Cranfield University at Silsoe, UK

-

Simple drilling methods. A technical brief which outlines simple, low cost drilling methods which may be used in different situations by B Elson and R Shaw, WEDC, Loughborough University, UK

-

Low-cost shallow tube well construction in West Africa by M. Sonou, FAO, Italy.

Hand drilling techniques are extremely effective in appropriate ground conditions but are not suitable beyond their hydrogeological limitations.

These webpages are intended to enable more information exchange and discussion on hand drilling. They are by no means exhaustive. Please tell us more about your hand drilling experiences, projects that you know about or equipment suppliers.

Are you new to manual drilling?

- If you want to learn about manual drilling techniques, the best place to start is Akvopedia: Drilling or digging, and then take a look at the manual drilling compendium to find out what others have already done!

Google Übersetzer

Google Übersetzer

Figure (above): Overview of countries where manual drilling potential has been mapped and when undertaken

Figure (above): Overview of countries where manual drilling potential has been mapped and when undertaken